CNC Grinding Service

Custom Precision Grinding Service

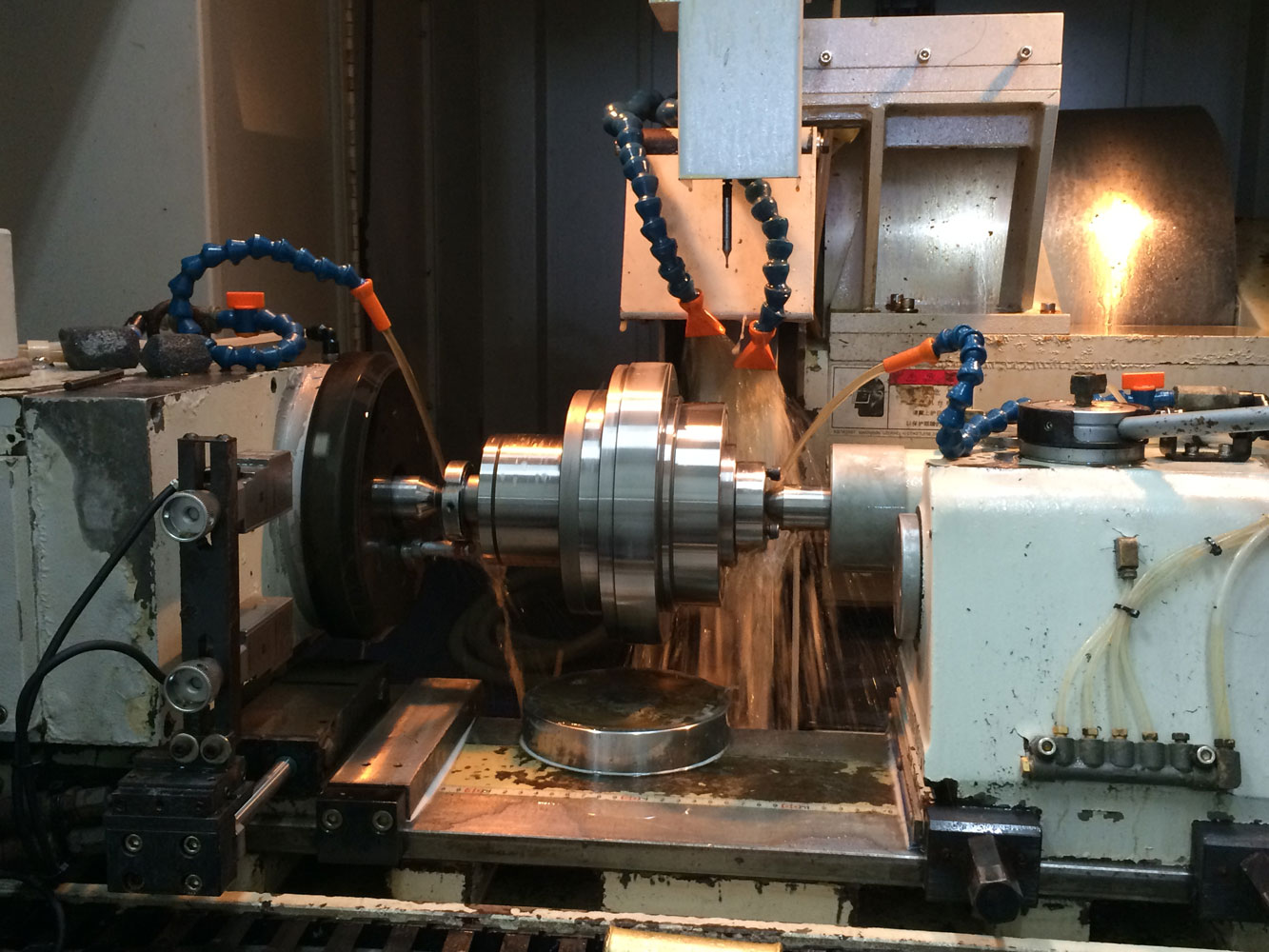

Located in Taichung, Taiwan, and with more than 30 years of experience in the steel sector, Ju Feng Grinding Center has advanced technology equipment, highly-skilled machinists and a temperature-controlled environment, which enables JFS not only grinding customized specifications, but also providing OEM services to meet customers' demand..

Ju Feng's engineering team uses computer numerically controlled grinding machines and dual-spindles grinders to provide high-volume precision grinding service. Ju Feng is an OEM service provider and also offer the services in precision inner dia. grinding, outer dia. grinding, and surface grinding with high tolerance and reliable quality.

Advantages

- High Tolerance

The min. tolerance of grinded parts Ju Feng’s team can offer is 2um. - Short Lead Time

According to customer’s demand, Ju Feng provides the standard, rush, and emergency delivery services. - Economic Benefit

The experienced machinists in Ju Feng’s grinding center is able to finish the parts with customer’s precise specification and save the grinding time due to our effective standard operation procedure.

Grinding Capabilities

- Tolerance: 2um (0.002mm)

- Grinded Material Size: Diameter: 10~400mm

- Grinded Material Types: Alloy Steel, Aluminum, Carbon Steel, Copper, Free Cutting Steel, Stainless Steel, and so on.

- Grinding Equipments: Surface Grinder, CNC Cylindrical Grinder, I.D. (Inner Diameter)/O.D. (Outer Diameter) Grinding machine, CNC Grinding Machine, CNC Dual-Spindle Grinder.

- Inspection Equipments: TESA Coordinate Measuring Machine, OD Micrometer, Caliper, Mitutoyo Bore Gage, Mitutoyo Electronic Height Gage, TESA Surface Roughness Tester.

- Grinded Product Types: Industrial components, Automobile parts, Sewing parts, Bearings, Sleeves, Gears, Collar, Needle tubing, Gaskets, Valve holder, Valve guide, Bevel gear, Shaft, Spindle, Washers, Valves, Die, Mechanical parts, and so on.

- Intended Industries: Industrial, Automobile, Electronic, Aerospace, Sewing, Agricultural, Chemical, Dental, Food, Medical, Military, Machine Tool, Pharmaceutical, Power Generation, Packaging, Semiconductor, Security, Transportation, and so on.

- Extended Services: Assembly, Anodizing, Boring, Bending, Broaching, Counter Sinking, Turning, Drilling, Deep Hole Drilling, Grooving, Heat Treating, Knurling, Laser cutting, Milling, Pressing, Plating, Planning, Reaming, Shaping, Sawing, Threading, Tapping, Welding.