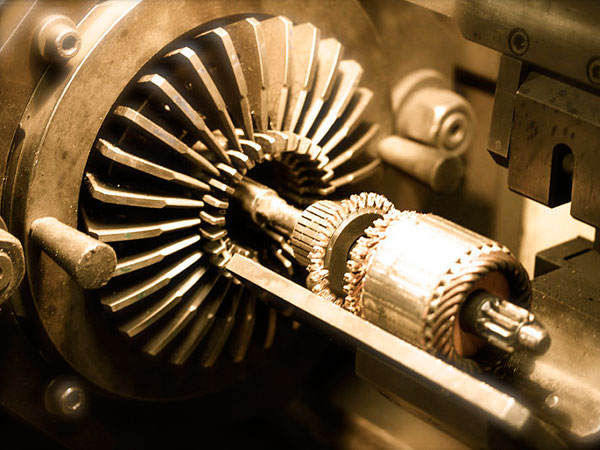

Machine Tool Spindle

The main shaft is the transmission axis in the machine, and is equivalent to the main axis in the heart of the machine.

There may be several spindles in a machine. There are many types of spindles, including grinding spindles, electric spindles, low-speed spindles, high-speed spindles, engraving machine spindles, milling machine spindles, lathe spindles, etc. Therefore, the spindle should be made of materials with the highest stability, rigidity and efficiency.

The materials for machine tool spindle application that we recommend are as below.

- Related List

SNCM439

Alloy Steel

Equivalent Grades: GB 40CrNiMoA, 45CrNiMoVA, JIS SNCM439, and ASTM 4340, 9840. SNCM439 is a kind of refining steel and has the properties of high hardness and toughness. It is often used for the manufacture of screws, gears, shafts, nuts, pistons, the automobile parts required high toughness and so on.

SNCM420

Alloy Steel

Equivalent Grades: JIS SNCM420 and ASTM 4320. SNCM420 is mainly used for railway bearings, drive shafts, gears, screws, cutting tools and other products which need impact resistance and wear resistance. SNCM420 is a kind of alloy carburizing steel as SNCM220. The mechanical properties between SNCM420 and SNCM220 are almost the same. The surface of SNCM420 is high hardness and has good performance in abrasion resistance and contact fatigue strength. Its core which has high toughness can withstand high impaction. There are two differences between SNCM420 and SNCM220 which are the standard and the amount of Ni content. The Ni content of SNCM420 is more than the one of SNCM220.

SNCM220

Alloy Steel

Equivalent Grades: GB 20CrNiMo, JIS SNCM220, ASTM 8615, 8617, 8620, 8622, DIN 20MoCr4. SNCM220 is mainly used for automobile bearings, drive shafts, gears, screws, cutting tools and other products which need impact resistance and wear resistant. SNCM220 is a common type of alloy carburizing steel or bearing steel with the surface of high hardness, abrasion resistance and contact fatigue strength. Its core which has high toughness can withstand high impaction.

SCM440

Alloy Steel

SCM440 is medium carbon chromium molybdenum alloy steel, which is an alloy steel containing chromium and molybdenum. It has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer and few surface defects. It is easy to be spheroidized and has low cold cracking rate. It is usually hardened and tempered. The ultimate tensile strength is 850-1000 Mpa. This material achieves a very good balance between strength, toughness and wear resistance. The chromium content of the alloy provides good hardness permeability, and the molybdenum element imparts average hardness and high strength.SCM440 reacts well in heat treatment and it is easy to process under heat treatment conditions. This material provides many desirable properties such as good strength and wear resistance, excellent toughness, good ductility and resistance to high-temperature stresses.

SCM420

Alloy Steel

Equivalent Grades: GB 20CrMo, JIS SCM420, ASTM 4118, DIN 25CrMo4. SCM420 are alloy steel with high hardenability, temper brittleness, well weldability, less cold cracking tendency, good machinability, and great cold plastic strain. SCM420 generally are used for the parts which need high wear resistance, such as gears, shafts, high-pressure pipes, all kinds of fasteners, and so on.

SCM415

Alloy Steel

Equivalent Grades: GB 15CrMo, JIS SCM415, DIN 15CrMo5. SCM415 whose surface are processed through carburizing hardening treatment are used for the parts which need high toughness or wear resistance, such as cylinder piston, crankshaft, gears, pin, shafts and so on.

S45CBD

Medium Carbon Steel

The surface is smooth after cold drawing, and the main difference with S45C is that the surface can reach rough turning of grade. The post-process can be directly used for milling or grinding, which greatly reduces the processing time. Its characteristics and application are the same as S45C. .Applications requiring strength and impact resistance of the component, because of its high carbon content, therefore, have a higher tensile strength, ductility and wear resistance, but is not suitable for welding or forming. This steel grade can be supplied in many standard shapes, including round, square, hexagonal, and plate. It generally applicative used in nuts and bolts, axles, rollers, springs, wires, wheel frames, rods, engine parts, stamping dies, hammers, lock washers/lock pin gaskets, turbine rotors, railway tracks, cylinder sleeves, hand tools, screws, railway wheels, gears, garden shears, etc.

S45C

Medium Carbon Steel

Applications requiring strength and impact resistance of the component, because of its high carbon content, therefore, have a higher tensile strength, ductility and wear resistance, but is not suitable for welding or forming.This steel grade can be supplied in many standard shapes, including round, square, hexagonal, and plate. It generally applicative used in nuts and bolts, axles, rollers, springs, wires, wheel frames, rods, engine parts, stamping dies, hammers, lock washers/lock pin gaskets, turbine rotors, railway tracks, cylinder sleeves, hand tools, screws, railway wheels, gears, garden shears, etc.